By Howard G. Murphy Jr.

With its significant proven reserves and production of coal, natural gas and natural gas liquids (NGLs), one might ask how West Virginia contributes to reducing individual and business global carbon footprints. The answer includes at least two paths—through the production of natural gas and NGLs to replace more carbon-intensive fuels and by using the natural gas pipeline infrastructure to facilitate the capture and use of renewable methane.

Defining Carbon Footprint

When people or businesses talk about reducing their carbon footprint, they are generally talking about reducing the production and release of greenhouse gas emissions into the atmosphere. Greenhouse gas emissions like carbon dioxide, methane, nitrous oxide and ozone are gases that cause solar radiation in the form of heat to be trapped in Earth’s atmosphere, affecting the atmosphere’s balance of heat gain and loss. The reduction of greenhouse gas emissions is a global strategy being adopted to varying degrees by virtually all developed and industrialized nations.

A business’s carbon footprint is directly related to its volume of greenhouse gas emissions. However, not all greenhouse gases have the same effects on the atmosphere. At the risk of oversimplifying a complex science, carbon dioxide is typically used as the baseline gas to which other greenhouse gases are referenced and is assigned a global warming potential (GWP) of 1. Methane has a GWP of approximately 28, and nitrous oxide has a GWP of approximately 265. The larger the GWP, the more adverse the gas is to the atmosphere.

Carbon intensity (CI) is another measure used to quantify one’s carbon footprint. CI is the amount of greenhouse gas or gases produced per specific amount of energy production. Approximate CI values for typical fuels include coal at 93, diesel and heating oil at 73, gasoline at 71, propane at 63 and natural gas at 53. As with the GWP, the larger the CI the more adverse the fuel is to the atmosphere.

Considering Economic Needs

With this basic backdrop, we can see that the types of fuels used by businesses and industries, and the specific types of greenhouse gases emitted, can have a significant effect on their carbon footprint. The ultimate goal is to use fuels and industrial processes that meet the economic needs of the business or industry while minimizing the GWP and CI. The importance of economic needs cannot be overstated and must be central to any carbon footprint reduction strategy.

West Virginia has abundant reserves of economically recoverable coal, natural gas and NGLs. In decades past, coal was the fossil fuel that provided 40 percent or more of the electric power generation capacity in the U.S. Coal continues to be produced for use as both a fuel for power generation and a feedstock for steel production and other downstream uses in the U.S. and other countries, but the advent of increased supplies of less expensive natural gas has cut coal’s share of the U.S. power generation fuel market in half. Couple that with CI values of 93 and 53 for coal and natural gas respectively, and the coal gets squeezed in most any carbon footprint reduction strategy.

Over the past 10 years, the technologies used to extract natural gas and NGLs have improved to levels previously unimaginable. In 2010, West Virginia produced approximately 265 billion cubic feet equivalent (BCFe) of natural gas and NGLs. In 2019, that value had increased to approximately 2,156 BCFe—an increase of over 700 percent. This production volume places West Virginia in the top seven natural gas-producing states and represents just over 5 percent of the natural gas and NGLs produced in the U.S.

When looking specifically at the electric power generation industry, a major source of greenhouse gas emissions globally, fuels that have the lowest CI and produce the lowest GWP would be fuels of choice in a carbon footprint reduction strategy. As mentioned previously, natural gas has a CI value significantly less than coal and fuel oil, supporting its use as a fuel to reduce one’s carbon footprint.

The economics for natural gas need to work as well—and they do. Between 2008-2018, the cost to generate electric power using nuclear; steam produced via coal, oil or natural gas; hydro; and gas turbine technologies changed. Using 2008 as the base year, the cost to produce one kilowatt hour of power increased or decreased for the four technologies as follows: Nuclear increased 10.4 percent, steam increased 0.3 percent, hydro increased 10.1 percent, and gas turbine decreased 54.1 percent. The reduction in gas turbine-generated power cost was almost wholly due to a reduction in the cost of the natural gas fuel. From an absolute value perspective, in 2018 the cost to generate electric power using gas turbine technology was 9.6 percent less than using steam.

Similar results occur when looking at the transportation industry, which is also a major global source of greenhouse gas emissions. In particular, diesel-fueled, heavy-duty trucks represent a significant opportunity to reduce the carbon footprint. Natural gas has a CI value significantly less than diesel fuel, supporting its use as a fuel in either compressed natural gas or liquefied natural gas (LNG) forms.

Methane V. Carbon Dioxide

While the results of fuel switching in the power generation and transportation industries appear compelling, how does one deal with the fact that methane, the primary component in natural gas, is a powerful greenhouse gas? The fact is that methane released into the atmosphere has 28 times the GWP of an equivalent quantity of carbon dioxide, but in these industries, methane itself is not released into the atmosphere. The combustion process that occurs within the gas turbine to produce electricity and the reciprocating engine to power the truck converts the methane to carbon dioxide, water vapor and relatively minor amounts of other substances.

In other industries, specifically the natural gas and NGL production, processing and pipeline industry, the release of methane directly to the atmosphere does occur. These releases occur during both normal and abnormal operations. While the amounts released are relatively small—estimates range from 1.4 percent to 2.3 percent of total production—they do occur. The industry has made and continues to make progress in reducing the volume of methane that escapes into the atmosphere.

Repurposing Gas Emissions

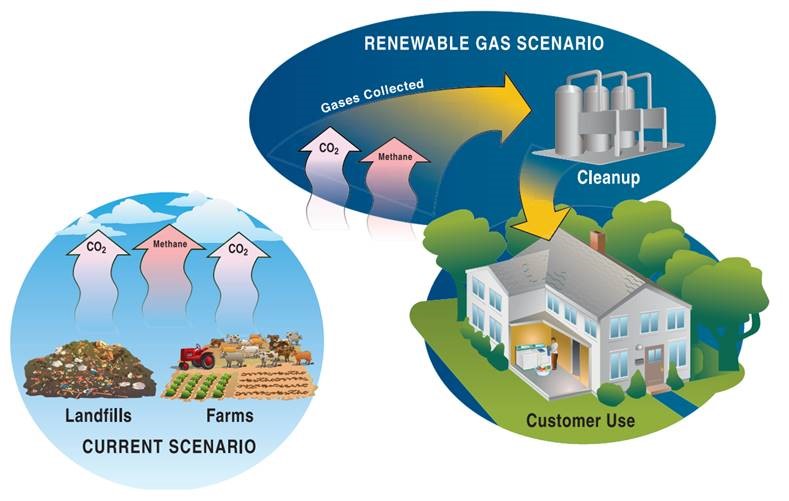

Even more interesting, there is the fact that methane releases from the natural gas and NGL production, processing and pipeline industry may represent approximately 20 percent of methane released from all sources associated with human activities. Other human-related sources include releases from landfills (31 percent of total), domestic livestock and livestock manure (28 percent of total) and coal mines (15 percent of total). A positive, meaningful impact can be made by capturing, for example, the methane and other gases released into the atmosphere at landfills and using the methane to fuel electric power generation instead of becoming a greenhouse gas.

The technology exists to capture releases from natural gas production or biogas from landfills and livestock operations. That methane can be added to the national natural gas delivery grid. This methane is known as renewable natural gas (RNG). However, the challenge to producing RNG is an economic one. The price of most fossil fuels, including natural gas, is currently so low that infrastructure costs needed to capture and clean the biogas do not justify the required investment using traditional investment metrics.

Nonetheless, the potential benefits in non-economic terms can be significant. When one factors in the greenhouse gas emissions—in this case, methane—that are no longer released to the atmosphere and are instead used to replace other fuels, the CI of the entire path, from livestock manure to heavy-duty truck fuel, can be zero or even negative. Under this scenario a problem—methane with a GWP of 28 entering the atmosphere—has a solution—the truck meets its intended purpose and emits carbon dioxide with a GWP of 1.

Reducing Emissions, Building Infrastructure

So how does West Virginia contribute to reducing individual and business carbon footprints? There are at least two ways. The first way is through the production of natural gas and NGLs that are sold into the domestic and global energy markets and available to replace and/or augment more carbon-intensive fuels. West Virginia produces far more natural gas and NGLs than it consumes and is a net exporter of these gas commodities. In today’s global economy, natural gas and NGLs from West Virginia likely become LNG and liquefied petroleum gas and reach end users in Asia and Europe, among others, helping those end-users achieve their carbon footprint reduction goals.

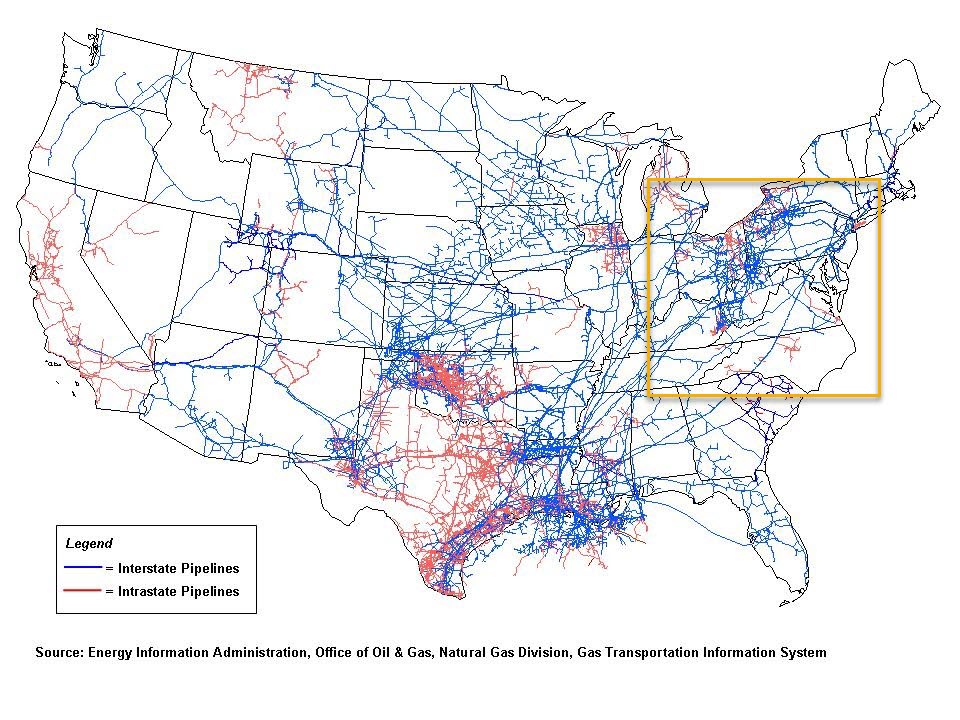

The second way is by providing market access and pipeline transportation for RNG produced from sources both inside and outside West Virginia. Development of RNG production projects can be highly dependent on the specific tax and subsidy treatment those projects qualify for within the state where the project is developed and within the state in which the RNG is ultimately consumed. Companies that develop RNG projects typically look to sell into the most lucrative markets, often requiring substantial pipeline transportation. West Virginia is crisscrossed by many pipeline operating companies, and many of these pipelines are interconnected. This interconnectedness provides developers, marketers and purchasers of RNG competitive options in delivering or receiving their RNG.

Whether one’s carbon footprint reduction strategy includes new or increased natural gas or NGL consumption, conversion of greenhouse gas emissions to RNG or pipeline transportation capacity, West Virginia stands ready to meet those needs.

About the Author

Howard Murphy Jr. is the director of energy services for EARTHRES. His career experience is wholly within the natural gas upstream, midstream and downstream business segments. He began his career with a gas transmission pipeline operating company providing engineering-based operations support. Since then, he has worked on the execution of capital projects and origination of pipeline transportation capacity projects and has managed commercial, technical and regulatory aspects of pipeline acquisitions, physical supply, capacity contracts and divestitures. Murphy has also worked in operations at a major U.S. liquefied natural gas import terminal at a major integrated gas and electric company. His current role at EARTHRES uses his years of working for operating companies to guide efficient and effective solutions for EARTHRES’ energy sector clients.

All opinions expressed in Executive Exclusives belong to the feature’s author and are not necessarily the opinions of the publishers or Executive Ink, LLC employees. West Virginia Executive and Executive Ink, LLC reserve the right to refuse any idea, material or subject matter.