Manufacturing Educational Initiatives

By Rachel Coffman

Chemical manufacturing is a tedious and technical process creating a challenge for the state’s manufacturers when communicating to the future workforce about potential careers. One manufacturer, Belle Chemical Company, has developed a robust educational outreach program to reach students from elementary through the university level across the state.

“Belle Chemical finds value in its numerous educational institutional partnerships because we want to promote the diversity of STEM related career opportunities that are available in the local community,” says Alicha Hunt, operations manager at Belle Chemical. “Our priority is to get kids started at a young age and continue to build upon their interests as they age.”

During the 2022-2023 school year, Belle Chemical, a methylamine and methylamide chemical intermediate producer located in Belle, WV, conducted a month-long manufacturing career engagement with over 400 students in eastern Kanawha County, established a simulated-workplace partnership with Carver Career & Technical Center’s graphic design program, developed two capstone programs with West Virginia University Institute of Technology’s (WVU Tech) chemical engineering program juniors and seniors and conducted a partnership with WVU Extension’s 4-H youth development annual outdoor classroom event for over 165 eastern Kanawha County fourth graders.

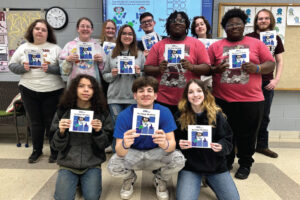

The theme of Belle Chemical’s educational engagements is providing real-world experiences for students. A unique approach focusing on art led Belle Chemical to establish a simulated-workplace partnership with Carver’s graphic design program.

“In our STEM engagements the previous year, we saw a gap in students connecting to what chemical manufacturing was and how we run our operations,” says Hunt. “We thought a coloring book would be the perfect tool for students to see and remember what manufacturing means and for them to connect when they see a plant facility.”

Denise Dodson, Carver’s graphic design instructor, and Belle Chemical developed the outline and copy for the book. The project, led by Carver senior Abigail Brandt serving as creative director, was designed by 16 students in the program with each student designing one page of the book.

“It’s highly important for corporate partners like Belle to interact and work with students on education projects,” says Dodson. “This project provided our graphic design students with practical experience and helped them develop relevant skills needed to move forward in the field of graphic design. Starting with client meetings, then developing ideas for the design, creating the page layout, making the corrections and receiving printing quotes, to actually seeing their hard work being printed as a final product, this type of experience gave my students the advantage to help them be better prepared for their future careers.”

Belle Chemical’s relationship with WVU Tech began in 2021 and expanded this year with the development of two capstone projects for the chemical engineering department’s junior and senior students, providing them with real-world scenarios to develop, process and work alongside the company’s engineers and sustainability professionals. The students were tasked with developing processes for using biodiesel for renewable energy to meet carbon emission

reductions for the company and designing a potential manufacturing process for dimethylethanolamine from Belle’s product, dimethylamine (DMA).

“I didn’t have any idea how DMA could be converted into something else; this project gave me the knowledge to see how a chemical like DMA can be manufactured into different products,” says Emily Henry Santamaria, a senior chemical engineering student who participated in the capstone. “Getting the input from those working in industry, this project prepared us for those experiences outside of the classroom.”

Throughout the year, these educational partnerships are a key priority for the 60-employee manufacturer. In total, hundreds of volunteer hours go into these educational engagements to provide the students across the state access to STEM outside of the classroom.